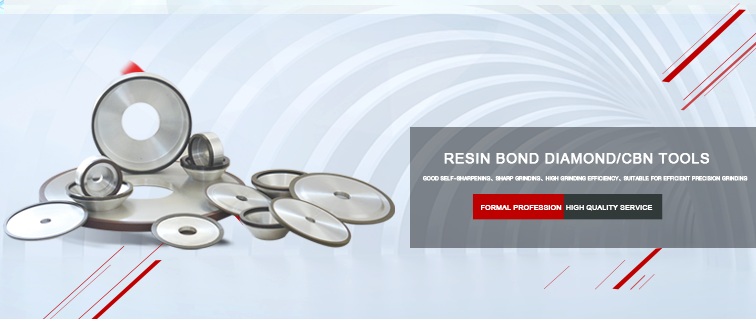

Precautions for Customized Diamond/CBN Tool Processing

发布时间:2023-06-27 文章来源:Original on this website 阅读量:948

When ordering grinding wheels, please try to provide us with the following information as much as possible1、 Please provide the specifications of the grinding wheel (outer diameter, substrate thickness, thickness of the abrasive layer, inner diameter, width of the abrasive layer), abrasive type, particle size, concentration, type of binder, grinding method (dry or wet grinding), and the material to be processed.2、 Please provide the processing method&Nbsp& Nbsp& Nbsp; Water mill, water cutting, dry cutting, dry grinding3、 Please provide granularity&Nbsp& Nbsp& Nbsp; Particle size selection: The larger and finer the mesh size, the smoother the workpiece produced by grinding.4、 Selection of binder&Nbsp& Nbsp& Nbsp; Resin bond (B), metal bond (M), ceramic bond (V);5、 Using concentration&Nbsp& Nbsp& Nbsp& Nbsp; Concentration refers to the proportion of diamond or CBN abrasives in the formula, which generally includes 50%, 75%, 100%, 150%, etc&Nbsp& Nbsp& Nbsp& Nbsp; Sintering (resin bond, metal bond, ceramic bond), electroplating, brazing7、 Working layer&Nbsp& Nbsp& Nbsp& Nbsp; Diamond tools generally consist of a working layer (abrasive layer) and a substrate (usually aluminum substrate, steel substrate, and bakelite).8、 Grinding wheel shape&Nbsp& Nbsp& Nbsp& Nbsp; Parallel grinding wheel, cylindrical grinding wheel, cup grinding wheel, bowl grinding wheel, butterfly grinding wheel, edge grinding wheel (refer to the shape diagram of the grinding wheel)9、 Supporting equipment&Nbsp& Nbsp& Nbsp& Nbsp; Workpiece name, material, hardness, machine name, type, rotational speed and horsepower, processing conditions and accuracy.If this is your first trial, you can provide us with drawings, samples, and related parameter descriptions&Nbsp; Structure diagram of commonly used grinding wheel shapes&Nbsp;&Nbsp;&Nbsp;Common Particle Size Comparison Table